RT273 Welded Pipe Mill Line is to produce round tube diameter of 165-273mm and wall thickness of 4.0-10.0mm.

We can also supply the customized machines.

RT273 Welded Pipe Mill Line is a series of machines that builds longitudinal weld seam pipe with steel strips of certain width. It starts by uncoil and flatten the slit steel coils into steel strips. The flattened steel strips will be inserted into the forming machine and the rollers in the machine will bend the strip to a round pipe shape. The round pipe will then be sent into the weld box where the tube is welded by a high frequency or solid state welder. The welded pipe will be formed to expected shape (round/ square/ rectangle etc) or size in a sizing machine. Finally the pipe will be cut to length and bundled.

Application

1. Water pipe

2. Heating pipe

3. Low-pressure process pipeline

4. Low pressure fire fighting pipeline

5. Sewage Pipes

6. Steel Scaffolding Pipe

7. Wire and cable protection pipe

8. Structural support Steel Pipe

9. Industrial Steel Pipes

10. Decoration Pipe

11. Oil & Gas Pipes

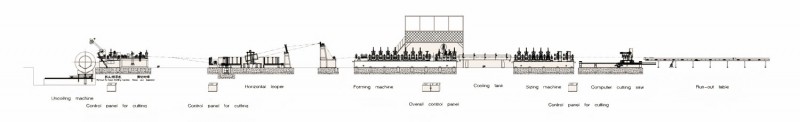

Process Flow

Slit Coil ---- Un-Coiler ---- Snubber Roller ---- Pinch Roll & Leveling Machine ---- Shearing And Butter Welder ---- Storage/ Accumulator ---- Forming ---- Welding ---- Cooling ---- Sizing ---- Cutting Saw ---- Run Out Table ---- Finishing ---- Pipe Collecting and Packaging

Technical Parameter

|

Model |

Diameter of Welded Tubes |

Wall Thickness of Round Tube |

Max. Size of Square Tube |

Max. Size of Rec. Tube |

Wall Thickness of Sq & Rec Tube |

Speed of Tube Welding |

Power of Major Motor |

High Frequency Power |

|

RT16 |

8-25mm |

0.3-1.0mm |

20x20mm |

12.7x25.4mm |

0.3-0.8mm |

20-100m/min |

30KW |

100KW |

|

RT25 |

8-32mm |

0.4-1.3mm |

25x25mm |

20x30mm |

0.4-1.0mm |

20-100m/min |

45KW |

100KW |

|

RT28 |

10-40mm |

0.5-1.5mm |

30x30mm |

20x40mm |

0.5-1.2mm |

20-90m/min |

75KW |

100KW |

|

RT32 |

13-50.8mm |

0.6-2.0mm |

40x40mm |

30x50mm |

0.6-1.5mm |

20-90m/min |

110KW |

150KW |

|

RT50 |

19-63.5mm |

0.8-2.5mm |

50x50mm |

40x60mm |

0.8-2.0mm |

20-90m/min |

132KW |

150KW |

|

RT50 to 76 |

19-76mm |

0.8-2.5mm |

60x60mm |

40x80mm |

0.8-2.0mm |

20-90m/min |

160KW |

200KW |

|

RT50 to 100 |

25-100mm |

0.8-2.0mm |

76.2x76.2mm |

50.8x101.6mm |

0.8-1.5mm |

20-80m/min |

160kw |

150kw |

|

RT60 |

19-63.5mm |

1.0-3.0mm |

50x50mm |

40x60mm |

1.0-2.5mm |

20-80m/min |

185KW |

200KW |

|

RT60 to 80 |

25-80mm |

1.0-3.0mm |

60x60mm |

40x80mm |

0.8-2.5mm |

30-80m/min |

75KWx2 |

200KW |

|

RT60 to 100 |

25.4-100mm |

1.2-2.5mm |

75x75mm |

50.8x101.6mm |

1.2-2.0mm |

20-60m/min |

185KW |

200KW |

|

RT76 |

25-90mm |

1.5-4.0mm |

70x70mm |

60x80mm |

1.5-3.5mm |

20-80m/min |

185KW |

300KW |

|

RT76 to 127-A |

50.8-127mm |

1.2-3.0mm |

100x100mm |

80x120mm |

1.2-2.5mm |

20-70m/min |

110KWx2 |

300KW |

|

RT76 to 127-B |

49-127mm |

1.5-4.0mm |

100x100mm |

80x120mm |

1.5-3.0mm |

20-70m/min |

110KWx2 |

300KW |

|

RT90 |

30-115mm |

1.5-4.5mm |

90x90mm |

80x100mm |

1.5-3.5mm |

20-60m/min |

132KWx2 |

300KW |

|

RT90 to 129 |

48-129mm |

1.0-2.5mm (550Mpa) |

101.6x101.6mm |

80x120mm |

1.0-3.0mm |

20-65m/min |

132KWx2 |

300KW |

|

RT90 to 140 |

60-140mm |

1.5-4.0mm |

110x110mm |

100x120mm |

1.5-3.0mm |

20-60m/min |

132KWx2 |

350KW |

|

RT115 |

32-127mm |

1.5-5.0mm |

100x100mm |

80x120mm |

1.5-4.0mm |

15-60m/min |

132KWx2 |

400KW |

|

RT115 to 140 |

60-140mm |

1.5-4.5mm |

110x110mm |

100x120mm |

1.5-3.5mm |

15-50m/min |

160KWx2 |

400KW |

|

RT165 |

89-165mm |

2.0-6.0mm |

127x127mm |

100x150mm |

2.0-5.0mm |

15-50m/min |

200KWx2 |

500KW |

|

RT219 |

114-219mm |

3.0-8.0mm |

165x165mm |

140x200mm |

3.0-6.0mm |

15-50m/min |

250KWx2 |

600KW |

|

RT273 |

165-273mm |

4.0-10.0mm |

210x210mm |

180x240mm |

4.0-8.0mm |

15-40m/min |

250KWx1 |

800KW |

|

RT355 |

219-355mm |

4.0-12.0mm |

280x280mm |

260x300mm |

4.0-10.0mm |

15-30m/min |

250KWx2 |

1200KW |

Machine Configuration

|

Entry Section |

||

|

Double Cone Un-coiler |

Hydraulic Expand with Coil Car |

|

|

Snubber Roller |

1set |

|

|

Pinch Roll & Leveling Machine |

2-roller + 5 roller |

|

|

Shear & Butt Welder |

Automatic |

|

|

Accumulator |

Horizontal |

|

|

Forming Section |

||

|

Pinch Roll |

2-roller |

|

|

Round shape Forming |

Normal |

|

|

Welding Section |

||

|

Guide Roll Stand |

1 set |

|

|

Extruding Roll Stand |

1 set |

|

|

Scraper |

2 sets |

|

|

H.F. Welder |

Solid State |

|

|

Cooling Unit |

Water cooling tank |

|

|

Sizing & Straightening Section |

||

|

Sizing Unit |

Normal |

|

|

Turk’s Head |

2 stations |

|

|

Measuring Roll Stand |

With encoder |

|

|

Flying Cutting Saw |

Pneumatic Friction Saw |

|

|

Run-out Table |

Singe side |

Double side |

Photos for Reference

Double Cone Un-coiler with Coil Car

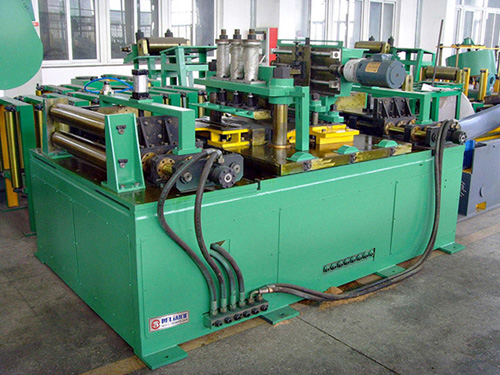

Snubber Roller, Pinch Roll & Leveling Machine

Automatic Shear & Butt Welder

Horizontal Accumulator

Forming Section

Water Cooling Tank

Sizing Section